B.S. Aerospace Engineering | Texas A&M University

Recent aerospace engineering graduate from Texas A&M University seeking full-time opportunities in the aerospace and defense industry. I thrive in team environments and have worked on real world projects that emphasize aircraft performance, control systems, and systems integration. Skilled in systems engineering, flight dynamics, and collaborative design. Looking for my next project. Eager to bring energy and technical skill to a forward thinking aerospace company. Download my resume.

Project Rattlesnake

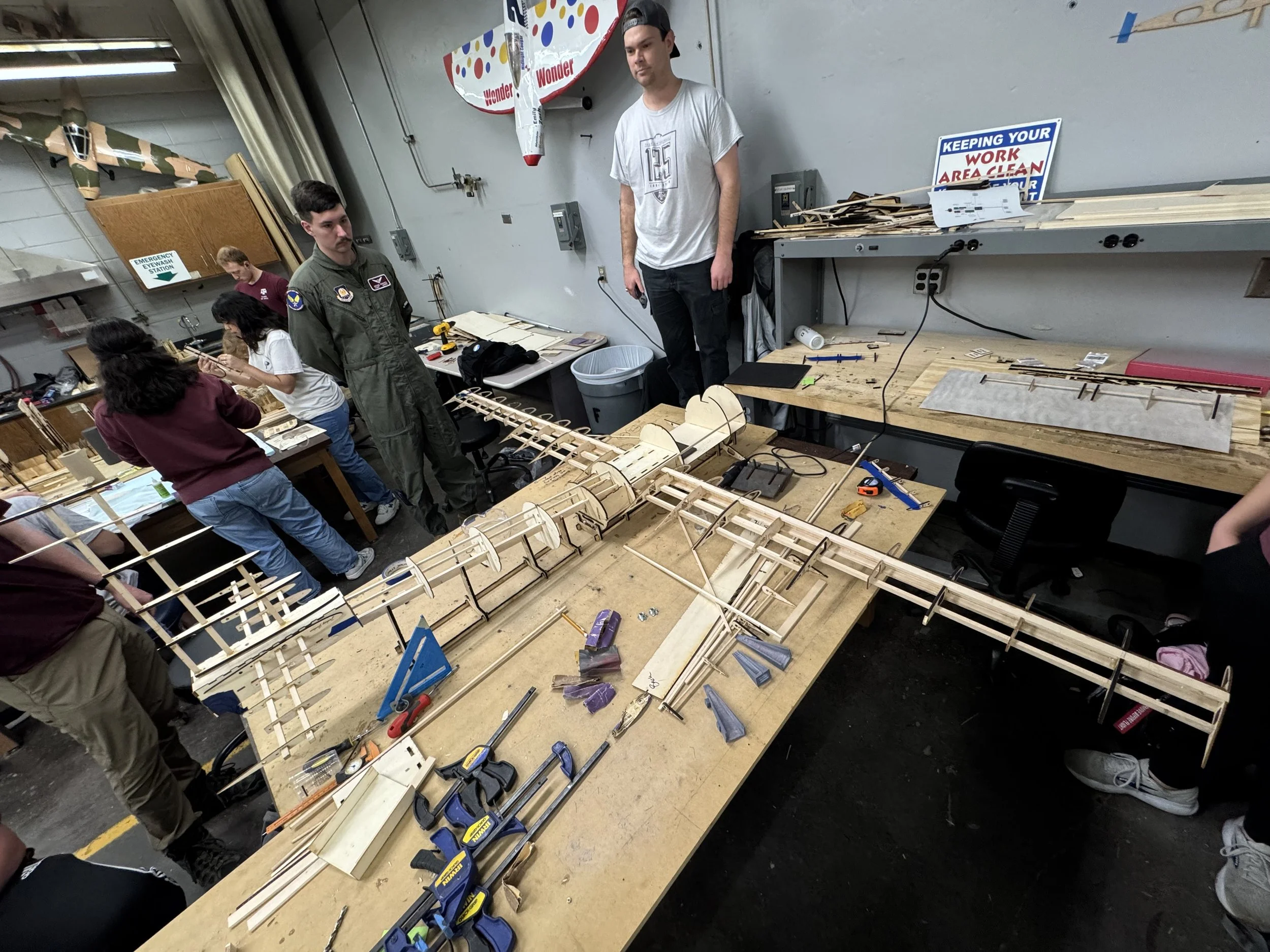

Project Rattlesnake is a long range, high endurance ISR UAV. It has a 9 ft wingspan, measures 5 1/2 ft from propeller to tail, and is constructed from 1/4 and 1/8 inch poplar plywood, basswood, balsa, and birch. The outer wings are detachable to allow for transport to Texas A&M Rellis Runway.

Project Rattlesnake

-

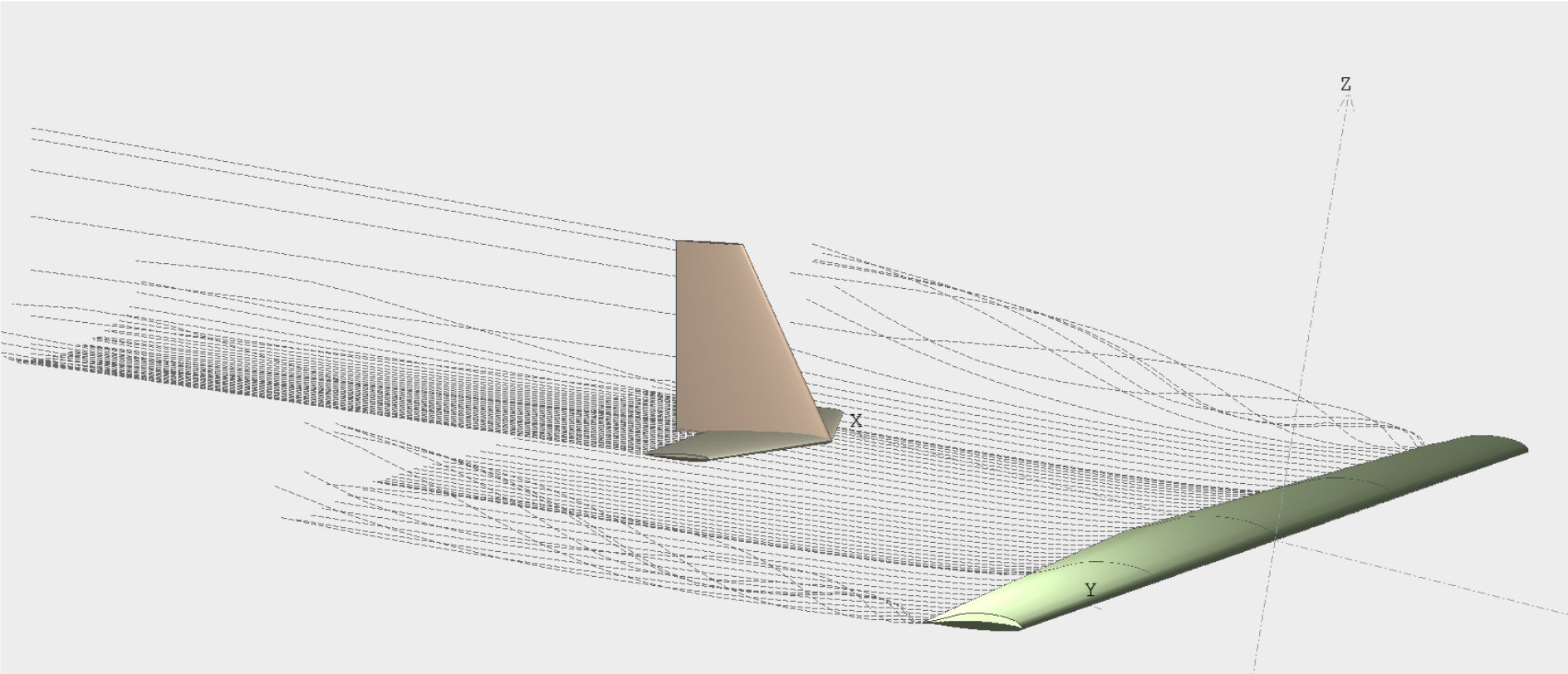

The team’s goal is to design a cheaper alternative UAS for the CBP fleet, that is optimally designed for a role in border security. During this time, CFD analysis was performed, aerodynamic design was finalized, and wind tunnel analysis was conducted.

-

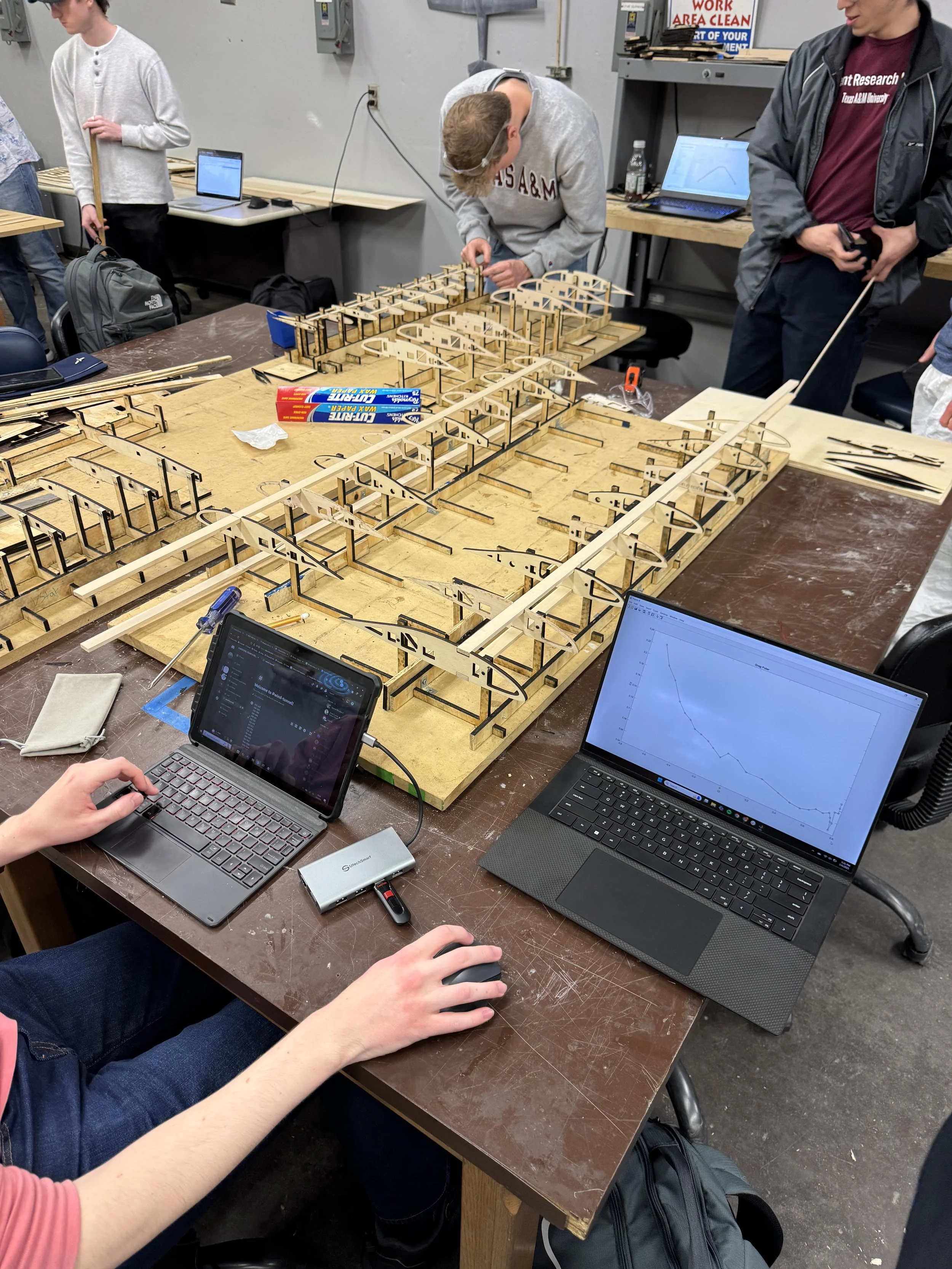

During the build, our ideas took shape. The laser cutter was used to print out jig parts, bulkheads, and wing ribs and webbing. A bill of materials is kept to track the budget and order supplies. Avionics were installed and wired throughout the plane.

-

The aircraft was taken out to Texas A&M Rellis Runway and flown of April 19, 2025. Two test flights were successfully completed. Flight data was collected and analyzed to improve our deign in the future.

Design

CFD analysis is run to see the airflow over the wing. During this time, all sizing of the lifting surfaces and control surfaces is finalized to ensure our control parameters are in an acceptable range. These control derivatives tell us how our airplane will fly, and extensive tests were performed to ensure optimization of our lift-to-drag ratio, optimizing range and endurance. The following image shows how our L/D vs. angle of attack improves over iterations.

CAD was performed on SolidWorks after CFD and sizing was finalized. Wing ribs and bulkheads were designed to be lightweight yet structurally significant. They were designed out of both 1/8” and 1/4” Poplar Plywood and balsa, with leading and trailing edges skinned by 1/64” birch. The wings were detachable and the spars transfered loads into the wing box.

These requirments were derived from class requirements, FAA requirements, and typical RC requirements. All requirements were deemded to have been met through a variety of simulations, and later on flight testing. After confirming requirements were met, the team created a 3D printed model out of PLA plastics to test our design in a wind tunnel at different elevator deflections.

After wind tunnel tests were performed, the data was collected, analyzed, and the results compared to our simulated results. The results show a general trend confirming our simulated values, but contains substantial error. Overall, no design changes were made and the build section is able to begin.

Build

Laser cutter printing wing ribs out of 1/4” poplar plywood.

Tools used:

Laser cutter

Sawzall

Dremel

Belt sander

Circle saw

Drill press

Band saw

Hand drill

The lifting surfaces, fuselage, and control surfaces were constructed on jigs.

The pieces were epoxied into components then removed from the jigs.

The components were carefully measured and then epoxied into a larger structure.

The structures are assembled to create the skeleton of the airplane.

Fly

Red line indicates the mean aerodynamic chord (MAC).

Center of gravity (CG) at 25.7% MAC

Aerodynamic center (AC) at 55% MAC

Static margin (SM) is 29.3% MAC

Pitching moment coefficient (Cmα) is -1.6 /radian

Maiden flight of the Rattlesnake through wind and rain.

PRISM

The Phobos Resource Identification and Sustainability Mission (PRISM) is a proposed human spaceflight mission focused on exploring Phobos, one of Mars’s moons, designed to pave the way for future crewed missions to Mars and beyond. As human exploration seeks to push new boundaries, it is paramount to test new technologies to understand possible challenges and learn how to overcome them. PRISM serves this purpose by targeting Phobos, which offers an airless, low-gravity environment where many of these technologies can be tested in a less complex setting.

PRISM

-

We began with NASA’s Request for Proposal, analyzing mission objectives, constraints, and success criteria. From there, we scoped PRISM as a short duration crewed mission to Phobos focused on autonomy, ISRU, and surface science.

-

Our team outlined the mission architecture and top-level concept of operations. We developed initial use cases, identified critical technologies, and defined the baseline mission flow, from launch to return.

-

Our team created a structured system breakdown. Major elements including habitat, scouting drones, and drilling subsystems were analyzed for interfaces, environmental constraints, and operational modes. We built an initial risk matrix and outlined mitigation strategies.

-

Subsystem designs were matured based on selected concepts. We defined communication protocols between crew, drones, and ground control. The habitat anchoring, power generation, and EVA safety strategies were all validated against environmental data.

-

We formally assessed risks in environmental hazards, system reliability, human health, and ISRU operations. Our team modeled off nominal scenarios and proposed design level mitigations such as sensor redundancy, regolith shielding, and human-robot supervision protocols.

Prism

Writing sample:

2.4.1 Crew-Robot Interface

A key element of PRISM is seamless coordination between humans and their robotic systems. The drones will be terrain scouting, drilling, and delivering samples, and the crew must maintain reliable oversight of the operations. This interface will be facilitated through wearable technology such as HUD EVA suits and tablets from within the habitat. Real time sensor feedback, including GPR data, drone telemetry, and terrain mapping overlays will be available during the EVAs. The interface will allow for both tactile control options, for precise controls during sample handoff, and reliance on AI systems that allow the crew to delegate routine tasks.

2.4.2 Habitat-Drone Interface

The temporary surface habitat will serve as the base of robotic operations. A dedicated station inside the habitat will allow for crew members to view live feeds, and analyze terrain maps, GPR scans, and environmental reports. Data from the drones will be transmitted wirelessly to the station and stored locally on hard drives. This interface will also allow for task queuing and drone diagnostics, allowing crew members to automate routine tasks. This interface will be loaded with redundancies to prevent data loss during comms outages and solar events.

2.4.3 Robotic Inter-System Communication

PRISM robotic architecture will support inter-system communications between various drones. Scouting drones will use LiDAR and GPR to transmit terrain and subsurface data directly to the drilling drones. This infrastructure forms the backbone of the mission’s robotic automation. These communications are controlled by a modular communications protocol that allows drones to share important information without the need for human interface.

2.4.4 Ground Control Interface

Due to communication delays between Earth and Mars, the PRISM mission requires a highly intensive ground control system to help optimize autonomous operations. Ground control will be responsible for high level mission oversight, planning, and problem resolution, while delegating day to day operations to the crew. This interface will allow for ground control to upload tasks and send software updates to the crew and robotic systems. Data from drones will be packaged together and sent to ground control to allow scientists on Earth to review and advise the crew and robotic systems.

2.5.1 Launch and Transit to Mars System Mode

The mission begins with the launch and transit phase. During this phase, all systems operate in a cruise configuration. Critical functions of this mode include life support, thermal control, radiation shielding, attitude determination and control, and ground control communications. The crew will follow a pre designed schedule focusing on system maintenance and monitoring, and mission preparation. Navigation and course corrections will be vital to ensure a mars orbital insertion. Radiation shielding will be active to protect against solar particle events. Drones, surface habitat components, and ISRU equipment will remain in storage. Ground control will maintain overall authority over crew members day to day activities during this time.

2.5.2 Phobos Orbital Insertion Mode

Upon arrival to Mars, the mission transitions to orbital insertion mode. The spacecraft will perform propulsion burns to achieve a stable orbit around Phobos. This mode requires precise navigation and coordination between onboard navigation systems and mission control. Once in orbit, the recon drones will be deployed to begin taking LiDAR and GPR data of the surface. These drones will map the surface and help ground control to locate a suitable landing location for the crew members and the ground habitat system.

2.5.3 Crewed Landing on Phobos Mode

Once a viable landing site is confirmed, the mission enters crewed landing mode. The crewed descent vehicle and habitat detach from the spacecraft and begin a controlled descent to the surface landing site. Due to the moon’s extremely low gravity and small mass, specialized thrusters will be needed to avoid bouncing off the surface or changing the orbit of the moon itself. Upon touchdown, the lander deploys anchors to lock on to the surface. Once surface stability is confirmed, the habitat will be deployed and power generation systems in the habitat will be turned on.

2.5.4 Surface Operations Mode

Following the successful deployment of the habitat and system diagnostics confirmation of life support systems, the mission enters the surface operations mode. This mode is the culmination of all the other modes, as this mode encompasses the main missions of the trip. The 90 day planned stay begins once the life support system is confirmed. At this point, the scout drones have scouted the surface enough to allow for mission planning by crew members and ground control. The tasks will begin to queue up for the drilling drones. EVAs will be planned to scout and confirm possible drilling locations for the drones. During EVAs, crew members will be employing biomimetic foot restraints and HUDs for navigation and monitoring. The drilling drones will optionally be deployed by the crew members to certain spots during EVAs and then they will autonomously return by thrusting into orbit. Crew members will control the drones using the crew-robot interface during sample handoff. Once a drilling site is established and the resources extracted have been confirmed as viable, the drilling drones will operate autonomously, incorporating information relayed by the scout drones, to continuously drill and deliver payloads to the ground habitat. Environmental sensors constantly assess radiation, surface temperature, and regolith composition for operational safety. This mode prioritizes efficiency, data collection, and system uptime, while also including system checks and downtime for crew health and safety. Ground control will maintain overall mission authority, but the crew will be responsible for their own day to day tasks and the robotic systems will be operating autonomously.

2.5.5 Return Mission Mode

The final phase of PRISM is the Return Mission Mode. This mode encompasses the crew departure from Phobos, rendezvous with the spacecraft in orbit around Phobos, and transit back to Earth. This mode begins with the activation and system check of the spacecraft, as well as the habitat shutdown and secure procedures. Crew members stow the drones and scientific equipment and transfer data for the return. Ground control and onboard navigational data will coordinate to choose the optimal thrusting procedures for an escape from Mars’ sphere of influence and a return to Earth’s.

2.6.1 Terrain Mapping and Subterrestrial Scanning

PRISM will use drones specially equipped with LiDAR and GPR to autonomously map the terrain of Phobos. These drones will be able to detect resource pockets large enough for mining operations. Data will be transferred in real time to the habitat for analysis. The crew will be able to identify ice pockets for extraction and begin to plane EVAs.

2.6.2 Ice Extraction and Processing

The mission will use autonomous drilling robots that can extract and transport ice without crew supervision. These robots shall be able to cover 50 miles, the entire circumference of Phobos with added range for emergencies, and transport the ice from any point on Phobos’ surface. The ice will be processed in the ISRU system within the habitat.

2.6.3 Habitat Life Support

The surface habitat will be able to support the four person crew for the full 90 day mission duration. It will provide life support, shield the crew from solar radiation, and provide thermal control. The crew and habitat will quickly be able to in-situ repair the habitat. The mined resources will be experimentally used to maintain life support, with redundant systems in place shall the experimental, in-situ life support fail.

Presentation sample:

Intergalactic Spacecraft

The Intergalactic Spaceship (IGS) enters the Milky Way on a hyperbolic orbit, the orbit parameters are displayed below. It is traveling at 110 km/s, and receives a total delta v of 97 km/s. This transfers IGS into Jupiter’s sphere of influence. It then uses the combination of Jupiter’s gravity and a second impulse burn to enter a circular parking orbit around Jupiter. This satisfies fuel usage and time requirements to enter Jupiter’s orbit. The mission sequence and sample code for an orbital manuever.

Culture, Camaraderie, Committed, Capable

References

Scott McHarg, Instructor

(979) 595-7990

smcharg@tamu.edu

Divya Bhargava, Professor

(979) 458-2158

bhargava@tamu.edu

Jeff Webster, CEO San Antonio Chamber of Commerce

(210) 473-6111

jwebster@sachamber.com

Contact Me

Want to learn more about a project? Interested in working together? Fill out some info and I will be in touch shortly. I can’t wait to hear from you!